Showroom

Control Panel Maintenance Service can

ensure that the electrical systems are operating effectively and safely,

prolong the life of the control panels, and lower the likelihood of equipment

failure. Regular control panel maintenance can be carried out on a quarterly or

annual basis, or it can be prompted by specific occurrences.

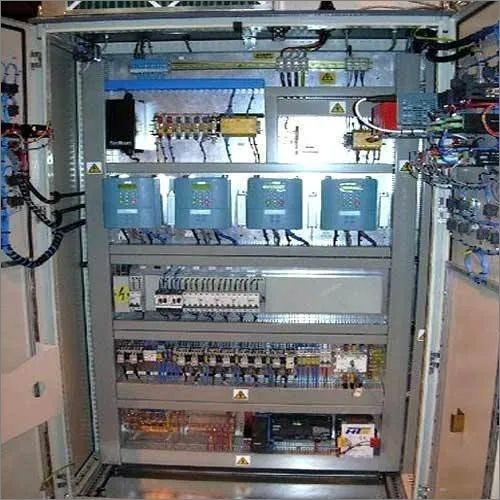

In order to ensure safe operation, Industrial

Control Panel might have safety features like interlocks, alarms, and emergency

stop buttons. Circuit breakers, relays, switches, controllers, and sensors are

among the electrical components that are typically housed in a metal enclosure

that serves as this panel.

The distribution Panel regulates how power

is distributed to various electrical loads throughout the building or facility.

This might contain meters, transformers, and other parts as needed to control

and keep an eye on the electrical system. It is made to provide a safe and

reliable way of distributing power to various loads.

Ginning Panel is employed in the cotton

ginning sector to regulate and keep track of the performance of cotton ginning

equipment. Cotton ginning, which separates cotton fibers from cotton seeds and

other debris, calls for specialized machinery and controls in order to be

carried out effectively and safely.

PLC Control Panel is a programmable logic

controller and other electrical components are housed in an electrical panel which

is used to automate industrial processes. Digital computers called PLCs are

used to monitor and control a variety of industrial machinery, such as motors,

sensors, valves, and other items.

Hospital Panel is an electrical panel that

is employed in hospitals and other healthcare facilities to supply a secure and

dependable power source to essential medical systems and equipment. It

typically consists of a metal enclosure that houses a variety of electrical

parts.

Feeder Pillar Panel is used to distribute

power from a primary power source to various circuits and loads in outdoor

settings like public spaces, industrial sites, and construction sites.

Transformers, metering equipment, and other elements that are necessary to

control and keep an eye on the electrical system may also be included.

LT Control Panel can be set up to carry

out a variety of tasks, including controlling temperature, pressure, flow, and

speed. In order to ensure safe operation, they might also have safety features.

Its design and construction must adhere to a number of industry and safety

standards.

Petrol Pump Control Panel is used to

regulate and observe the operation of petrol pumps at filling stations. Fuel

dispensing to vehicles and other equipment is made safe and dependable by these

control panels. They require very low maintenance and replacement costs.

Drive Panel is an electrical panel that

houses motor drives that are used to regulate the speed and torque of electric

motors, such as variable frequency drives or other motor drives. This panel is

frequently employed in industrial settings to control the operation of

conveyors, pumps, fans, and other machinery.

|

MADHAW ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry